White Ink

Digital printing relies on the color of the substrate (primarily white) to provide pop and saturation. When printing on clear substrates, graphics will appear translucent and washed out without that white backing. The solution is to add a white ink layer under the printed graphic. This allows the graphic to retain transparency where needed while giving opacity and pop to the printed areas.

First-Surface vs. Second-Surface Printing

You may have heard this terminology when printing to clear materials, but what does it mean?

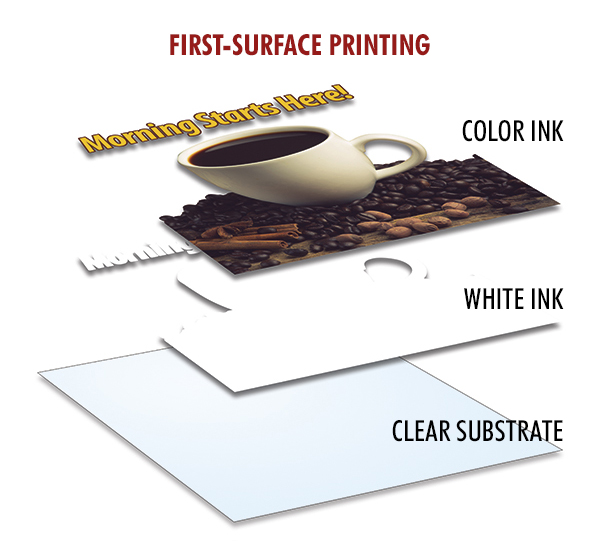

First-Surface Printing

First surface refers to printing, or mounting, a graphic to the viewing side of a substrate. In the example, our clear substrate will receive a white ink layer followed by a full color layer. All the ink is on the first surface.

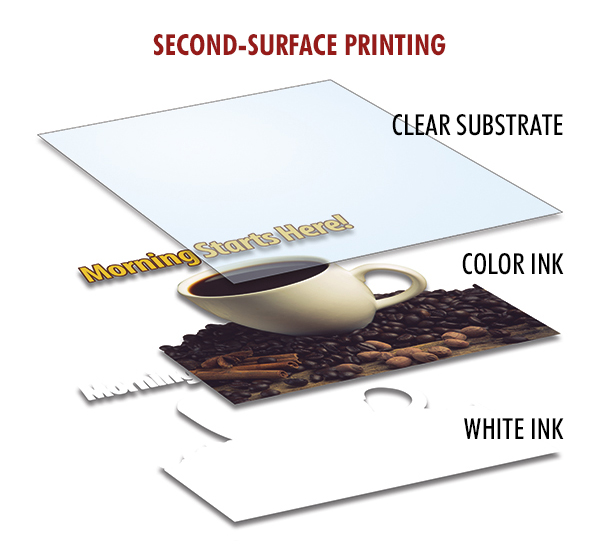

Second-Surface Printing

Second surface reverses the process. All ink is printed on the back of the clear substrate in reverse order—color first followed by white. This allows the substrate to act as a protective layer for the graphic. Second-surface printing can also be done on PSV or window clings so they can be adhered to the inside of a window and seen as right-reading on the outside.